Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Servomotor SEW

CMP.. series synchronous servomotors

The length-optimized CMP.. servomotors offer precision, high dynamic characteristics and power in a particularly compact design. 7 high-performance sizes cover peak torques up to 320 Nm and can be used in the tightest of spaces.

Our CMP.. series of synchronous servomotors can adapt to high loads or to the highest dynamic requirements. Whether in the food and beverage industry or the construction, automotive or wood industries: these synchronous servomotors can be used anywhere to achieve fast cycle times or to move the heaviest loads easily and precisely. Thanks to their optimized length, you can use the CMP.. motors even in the tightest spaces.

The highly dynamic CMP.. servomotors round out our range of servomotors: they offer standstill torques of 0.5 Nm to 95 Nm with 7 motor sizes and a total of 31 motor grades. State-of-the-art winding and magnet technology make the servomotors extremely low in inertia, even though they are optimized for performance. The result is a motor system with the highest possible dynamic characteristics.

Your benefits

Highest dynamic characteristics

thanks to the modern winding and magnet technology – over the entire speed range, of course.

Precise positioning

thanks to the high-performance rotor of the CMPZ.., even under extreme loads.

High-performance brake

since different brake systems with scalable braking torques and a manual brake release option are available.

Custom-tailored drive solutions

because the motor can be directly mounted on a gear unit from our proven modular gear unit system.

Features

Highest dynamic characteristics throughout the entire CMP.. range thanks to the low-inertia rotor design and high overload capacity of the motors

Performance-optimized and extremely compact design thanks to the latest winding and magnet technology

Standstill torques from 0.5 Nm to 95 Nm

Optional CMPZ.. motor variant with increased rotor inertia for all applications with high load moments of inertia

High quality of concentric running characteristics

Direct mounting of the motor on a gear unit from our modular gear unit system

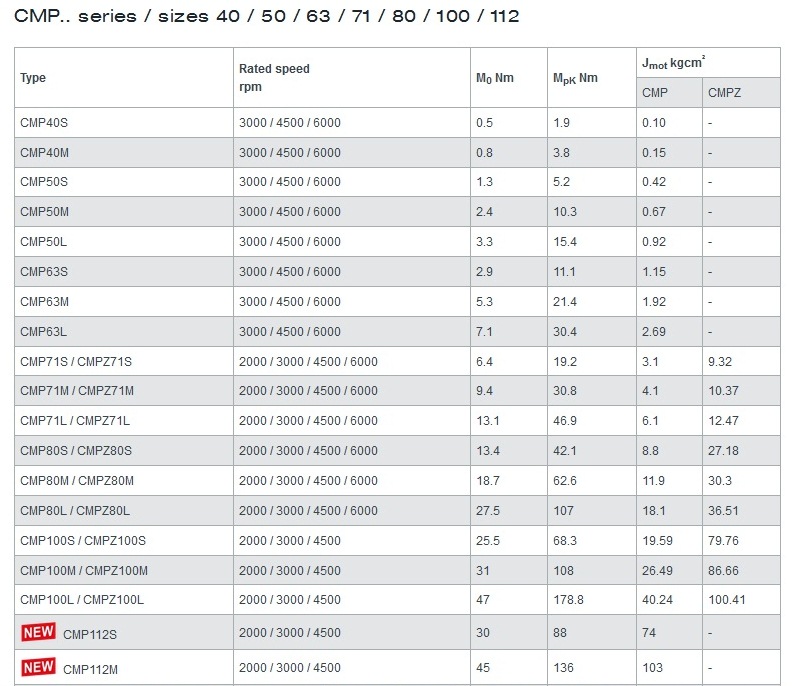

Technical Data :

Areas of application

Food industry

Beverage industry

Construction industry

Automotive industry

Timber industry

Catalogue of CMP.. series synchronous servomotors

CM.. series synchronous servomotors

The synchronous servomotor for highly dynamic applications. High performance, precision and reliability are the trademarks of the CM.. series. 3 sizes allow for maximum torques up to 238 Nm.

Dynamic, able to withstand high torques and with optimal control characteristics. Our CM.. series of synchronous servomotors are ideal for a wide range of application conditions. Simple bottle control or secondary packaging tasks are no problem for our servomotors. This series can position objects of virtually any inertia value with precision and accuracy. Regardless of the application. They are as effective for equipping a gantry robot as for a storage/retrieval system.

With 3 motor sizes, each with 3 different lengths (4 lengths for the largest size), our servomotors cover a standstill torque range of 5 Nm to 68 Nm. Equipped with high-energy NdFeB magnets, these units can help your system achieve excellent overload behavior of 400% of the standstill current. With us, that comes standard. The state-of-the-art magnetic circuit technology also ensures high true-running accuracy and low torque ripple (cogging).

Your benefits

Excellent overload behavior

thanks to NdFeB magnets – 400% of the standstill current as standard.

Flexible installation

because the servomotors can be integrated into the machine as a direct drive and combined with virtually any gear unit without need for an adapter.

Reliability of use

because the motors of the CM.. series excel in all application areas thanks to their especially durable construction.

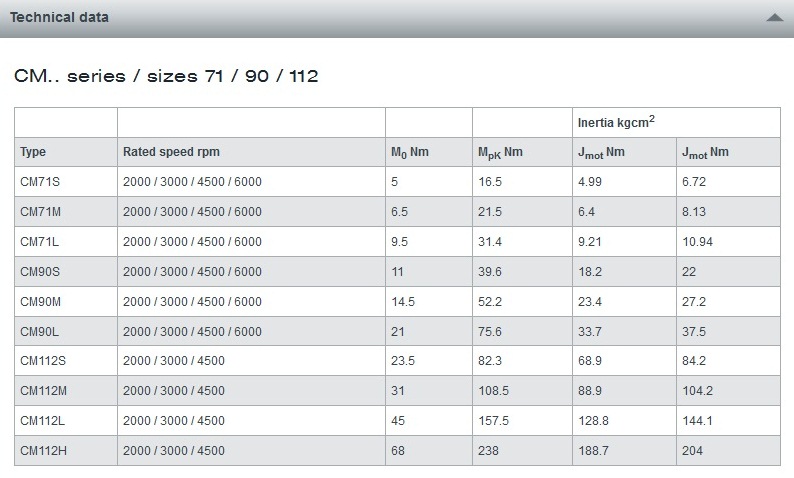

Technical Data :

Features

Standstill torques from 5 Nm to 68 Nm

Compact design with high power density thanks to an optimized magnetic circuit design

High overload rating and low losses

Electronic nameplate for quick and simple startup

Optional: scalable HIPERFACE® encoder and high-performance working brake

Areas of application

Food industry

Beverage industry

Handling and logistics

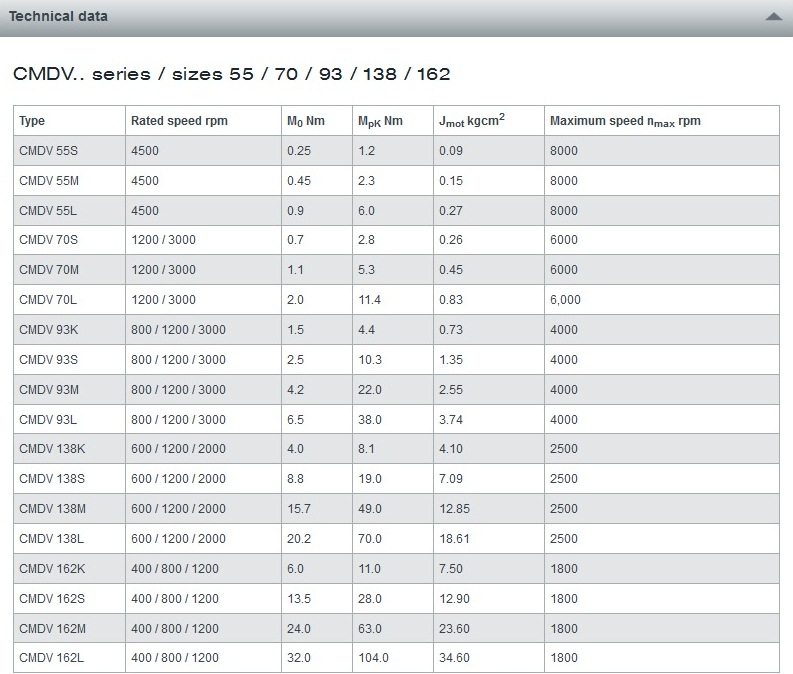

CMDV.. series synchronous servomotors

Our compact servomotors. They have been designed and optimized for direct motor mounting. Even with their extremely compact designs, the 5 motor sizes produce standstill torques of 0.25 Nm to 32.0 Nm.

Rugged bearings and a low-vibration design – this compact servomotor is the ideal device for applications with limited installation space and for all directly driven servo applications. The innovative design of the synchronous servomotors, including the latest in winding and magnet technology, offers a wide variety of standstill torques as well as high overload capacities.

The standstill torques range from 0.25 Nm to 32.0 Nm, with up to a six-fold overload capacity. 5 compact motor sizes in a convection-cooled design without a housing.

Your benefits

Compact installation

thanks to the slim design and short profile of the servomotors.

Quick startup

using prefabricated cables and an electronic nameplate.

High overload capacity

for quickly generating and dosing pressure or for positioning stops and clamping devices.

Reduced wear

because mechanical components such as gear units, spindles and toothed belts are not required in certain applications.

Technical Data :

Features

Optimized speeds for direct motor mounting

Particularly short length

Suited as direct drive

Innovative design with state-of-the-art winding and magnet technology

Convection-cooled design without housing

Standstill torque range from 0.25 Nm to 32.0 Nm

Equipped with thermal motor protection and resolver feedback as standard

Optional: scalable HIPERFACE® encoders with electronic nameplate and 24 V holding brakes

High degree of protection IP65

Areas of application

Packaging machines, also in the food and pharmaceutical industries

Paper processing machines

Printing machines

Wood processing machines

Handling systems

Transport systems

Glass processing machines

Plastic manufacturing and processing machines

Catalogue of CMDV.. series synchronous servomotors

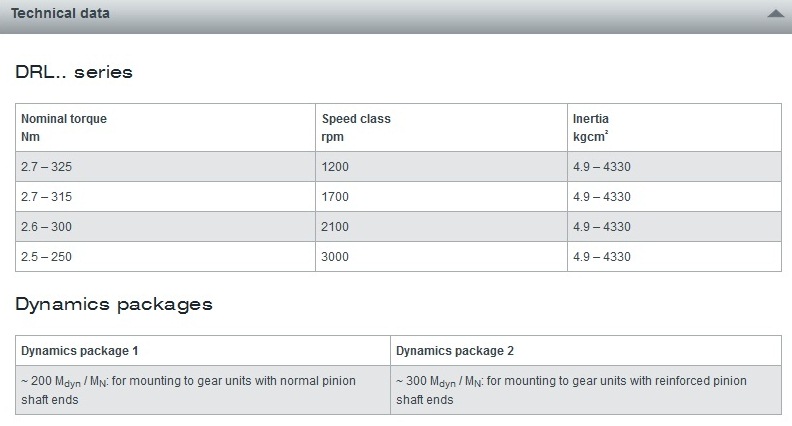

DRL.. series asynchronous servomotors

The link between the classical AC asynchronous motors for supply system/inverter operation and the highly dynamic synchronous servomotors with permanent magnets.

DRL.. asynchronous servomotors are particularly suitable when high external mass moments of inertia in relation to the motor shaft have to be controlled in a reliable manner. The design and dimensioning are of such a high quality that dynamic overload values of currently up to 350% can be reached for a short time. The overload capacity is divided into two dynamics packages.

The DRL.. series also has the required torque. With its four speed classes and a high-resolution sine/cosine encoder, a high speed quality is achieved – even at low speeds.

Our asynchronous servomotor also allows you to benefit from many additional features of the modular motor system of the DR.. series.

Your benefits

Reliable control

as a load of up to 3 to 4 times the nominal motor torque in relation to the motor shaft can be achieved.

High speed quality

in one servo gearmotor by means of a compact unit comprising gear unit and robust asynchronous servomotor.

High accuracy

by reducing the circumferential backlash in conjunction with high efficiency and high-endurance gearing.

Technical Data

Features

Torques from 5 Nm to 200 Nm

High rated torques for high dynamic loads

Load of up to 3 to 4 times the nominal motor torque

Safe and exact positioning in conjunction with MOVIAXIS® multi-axis servo inverter or MOVIDRIVE® application inverter

Areas of application

Gantry order picking robots

Travel axes in palletizers

Winding drives and cutter drums

Lifting axes in gantries

Conveyor applications

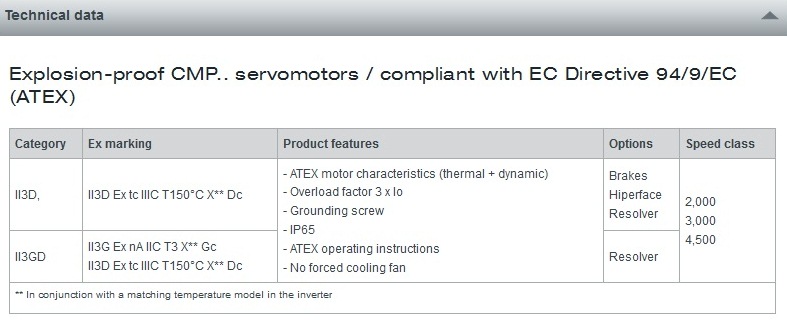

Explosion-proof servomotors

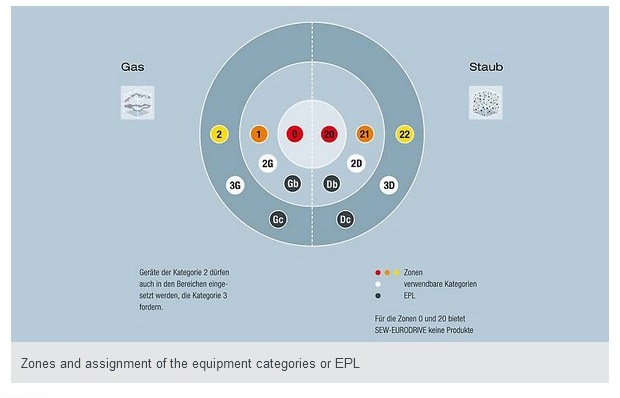

Adding precision and safety to your system with explosion-proof servomotors; ATEX-compliant motors can be used in environments with explosive air/gas or air/dust mixtures according to category 3.

Implement our servo drive technology in potentially explosive areas! Precision, dynamics and performance in a particularly compact design. Potentially explosive environments are no problem with our servomotors.

Choose the right ATEX-compliant servomotor from a range of 6 sizes, CMP.. 40 to 100. Torque range from 0.5 Nm up to 47Nm standstill torque. Safe design and additional protective measures meet requirements according to EU Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX). They are also available with different protection types depending on the atmosphere, i.e. gas or dust.

In terms of their safety requirements, the servomotors comply with equipment group II. In simple terms: You can use these category 3 explosion-proof motors in gas zone 2 or dust zone 22.

Your benefits

Flexible use

You can reliably operate our explosion-proof motors in both hazard zones, in gas or dust atmospheres.

Highest dynamic characteristics

through state-of-art winding and magnet technology - across the entire speed range as a matter of course.

Tailor-made drive solutions

realized by directly mounting the motor to explosion-proof gear units from our proven modular gear unit system.

Technical Data :

Features

As a system operator, special guidelines apply for areas with explosive air/gas or air/dust mixtures. We naturally observe these guidelines when newly developing or improving explosion-proof drive technology. Put your trust in our many years of experience and expertise!

Explosion-proof servomotors of the CMP.. series

Compliant with Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX), equipment group II, equipment category 3

Category II 3GD, for use in zones 2 / 22

Category II 3D, for use in zone 22

Also available with brake and Hiperface® encoder (with electronic nameplate) in Category 3D

Areas of application

Applications in potentially explosive atmospheres with air/gas or air/dust mixtures according to directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX).

e.g. agitators, mixers, paint shops, robots

Examples:

in the automotive industry

in the food and beverage industry

in intralogistics

in the timber, construction and construction materials industry

in the chemicals/pharmaceuticals industry

in special applications, e.g. in biogas systems

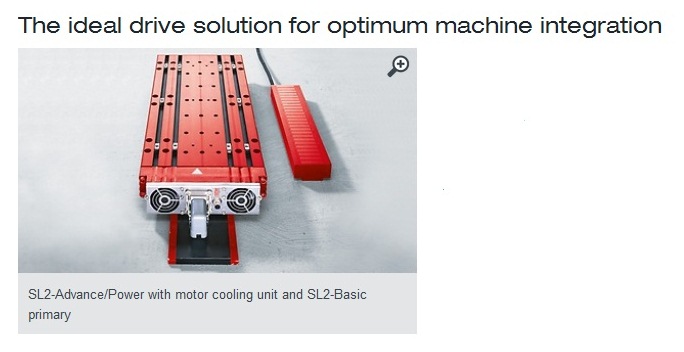

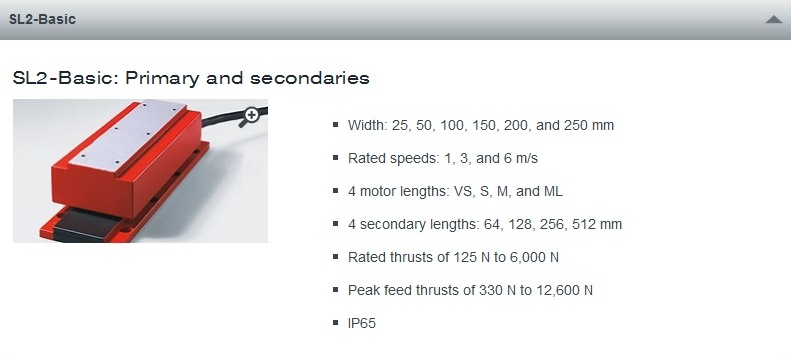

SL2 synchronous linear servomotors

Our SL2 synchronous linear servomotors are ideal for handling tasks, pick-and-place applications, and synchronous processing.

The already high demands placed on machine cycles, acceleration, and linear traveling velocities in many areas such as handling, transportation, and production are continuing to increase steadily. At the same time, users of these demanding systems attach particular importance to the use of virtually wear-free and maintenance-free drive technology. The convection-cooled direct drive covers all requirements to ensure rigorously high control quality with powerful dynamics and consistently high precision levels.

Specially designed for process reliability. Because linear motion and force is generated directly, the linear motors do not require mechanical transmission elements or wear parts, such as spindles, ball bearings, or toothed belts. In addition, the latest winding technology and laminated iron core required for this ensure an optimum force-density ratio.

There are 3 motor versions available: SL2-Basic, SL2 Advance System, and SL2 Power System. All motors are available in several widths and lengths, and in speed classes 1, 3, and 6 m/s. Your flexibility is also important to us: The secondaries for the linear motors are available in different lengths and can be lined up easily, if required.

Your benefits

Powerful dynamics

High travel speeds and optimum positioning allow the achievement of powerful dynamics.

Simplified project planning

No need to check the ratio between the motor’s moment and the external moment of inertia.

Reduced maintenance

Wear parts such as spindles, ball bearings, and toothed belts are no longer required.

Reduced noise levels

Less noise produced, even with high supply voltages.

Technical data :

Features

No mechanical transmission components or wear parts are required as linear motion and force are generated directly

Optimized force-density ratio thanks to the latest winding technology and laminated iron core

Virtually maintenance-free

High control quality, dynamics, and accuracy

Available in three designs: SL2 Basic, SL2 Advance System, SL2 Power System

Secondaries available in three different lengths; can be lined up easily

Areas of application

Highly dynamic, flexible processing machines

Material handling environments

Pick-and-place applications

Catalogue of SL2 synchronous linear servomotors

* For more information and buy SEW equipment , kindly contact sales department.