Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Explosion-Proof Motors - SEW

Explosion-Proof AC Motorts - SEW

Explosion-proof AC motors

EDR.. explosion-proof motors bring safety and performance to your system: whether according to ATEX, IECEx or HazLoc-NA®. The EDR.. motor series features 13 sizes and can be used in environments with explosive air/gas mixtures and/or air/dust mixtures.

No compromises in hazard zones: high-performance, EX-compliant motors

You can rely on our drive technology, even in potentially explosive atmospheres. There is no need to make any compromises either in terms of safety for your application or in terms of the variety of performance levels of the drives used.

This is because our explosion-proof AC motors from the EDR.. series comply with the most important international standards and directives.

They meet all requirements for tools and fixtures intended for use in potentially explosive atmospheres as defined in EU Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX). They are also available with different protection types or IP degrees of protection depending on the atmosphere, i.e. gas or dust. In terms of their safety requirements, motors from the EDR.. series comply with equipment group II. In simple terms: You can use these explosion-proof motors in categories 2 and 3, in gas zones 1 and 2, and in dust zones 21 and 22.

Directive 2014/34/EC has been applicable since February 26, 2014 for devices and protective systems for designated use in potentially explosive atmospheres. This directive replaced directive 94/9/EG.

Declarations of conformity according to the new directive cannot be issued until April 20, 2016.

The motors are available with IECEx certification according to EPL b and c (Equipment Protection Level) for countries that recognize IECEx regulations.

HazLoc-NA® motors comply with the Class Division System and are certified by CSA for use in Division 2 Class I (gas) and Class II (dust).

The motors come in 14 sizes from 63 to 315 which cover a power range from 0.12 kW up to 175 kW (50 Hz) or 200 kW (60 Hz), ensuring varied levels of performance. We thus enable you to avail of countless drive combinations for the most diverse systems and machines in potentially explosive atmospheres.

Your benefits

Remain flexible

whether in a gas or dust atmosphere, you can reliably operate our explosion-proof motors in both hazard zones.

Be safe

thanks to their approval according to EU Directive 2014/34/EU (ATEX) the motors can be used all over the world.

Features

As a system operator, special guidelines apply for areas with explosive gas/air and dust/air mixtures. We naturally observe these guidelines when newly developing or improving explosion-proof drive technology. Put your trust in our many years of experience and expertise!

Explosion-proof AC motors of the EDR.. series

* EDRE.. motors conform to the efficiency class IE2 in accordance with IEC 60034-30-1 and/or High in accordance with NEMA MG-1

Approvals for the motor were performed according to the latest European standards applicable to explosion protection:

General requirements IEC/EN 60079-0, gas IEC/EN 60079-7, IEC/EN 60079-15 and dust IEC/EN 60079-31

Compliance with the internationally applicable Equipment Protection Level EPL

EDR.. series motors comply with the most important standards and meet the IEC 60034 motor standard.

The motors have been certified by the PTB

* Approvals for the North American market in accordance with NEC500 and CSA22.2

Certification by CSA

according to the Class and Division System

* Are suitable for operation on a frequency inverter, also in field-weakening operation, for categories 2 and 3 and/or EPL b and c, or in Div 2

* Compliant with EC Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX)

Can be used in categories 2G, 2GD and 3GD, 3D for zones 1 / 21 and 2 / 22

Also available with a brake, encoder and forced cooling fan in category 3

Compliant with IECEx

In accordance with IECEx to EPL Gb and Db as well as Gc and Dc

EDRS and EDRE motor types in accordance with the IECEx Certified Equipment Scheme with ExTr, QAR, and CoC audited and certified by PTB;

further information on the certification system is available on the website of the International Electrotechnical Commission (IEC)

* In accordance with HazLoc-NA®

Meet the efficiency requirements according to EISA 2007 and CSA C390-10 for the North American market

Motors are certified according to the Class Division System (NEC 500, CSA22.1) and therefore meet the explosion-protection requirements for the North American market

Available as CID2 type, for Division 2 Class I for gas groups A, B, C and D

Available as CIID2 type, Division 2 Class II for dust groups F and G

Available as type /CICIID2, for Division 2 Class I for gas groups A, B, C and D and Class II for dust groups F and G

Also available as brakemotor with hold function

Operation on a frequency inverter possible in Class I and Class II

No power reduction

Setting range 1:6 to 1:10 possible

Speed up to 3000 rpm

Optional encoder mounting adapter for mounting encoders

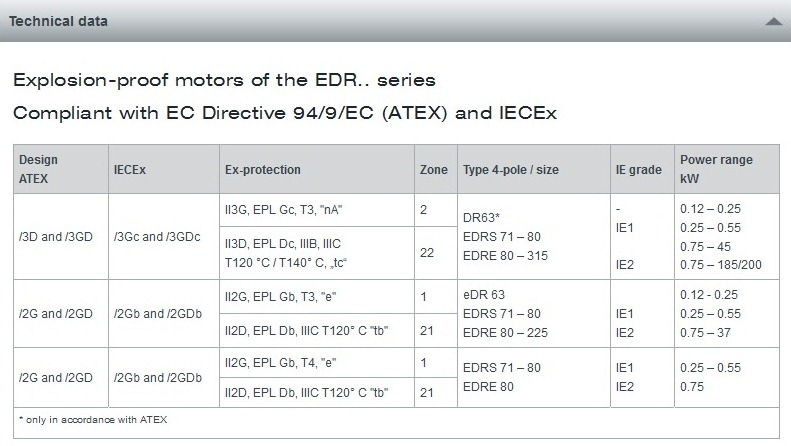

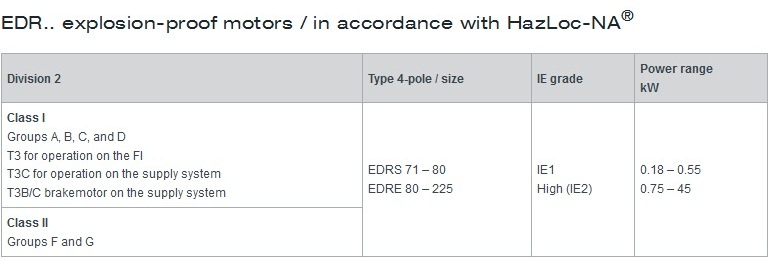

Technical data :

Areas of application

in potentially explosive atmospheres with air/gas or air/dust mixtures according to Directive 94/9/EC (ATEX), or as of April 20, 2016 of the EU Directive 2014/34/EU (ATEX) and in accordance with HazLoc-NA®.

Waste water and sewage treatment plants

Construction materials processing

Materials handling applications

Wood processing

Process applications in the chemicals and pharmaceutical industry

Application examples:

Corner transfer units

Extruders

Travel and lifting drives in storage/retrieval systems

Screw conveyors

Belt conveyors

Hoists and lifting stations

Chain conveyors

Freight elevators

Pallet conveyors

Gantry cranes

Presses

Pumps and fans

Roller conveyors

Rotary tables

Scissor lift tables

Fans

Catalogue of Explosion-Proof Motors / SEW

* For more information and buy SEW equipment , kindly contact sales department.