Welcome to karoon khozestan co

- Group:

- Type:

- Brand:

Ac motors - SEW

DR.. and DT56 series AC motors (1 speed)

We offer you the ideal AC motor for any requirement: 2, 4 and 6-pole motors, with powers of 0.18 kW to 225 kW and in the efficiency classes IE1 to IE4. Give us and our DR.. series motors a try!

IE1 to IE4 motors: efficient, powerful and usable worldwide

With the DR.. modular motor system, we implement millions of drive combinations and move different systems and machines, worldwide.

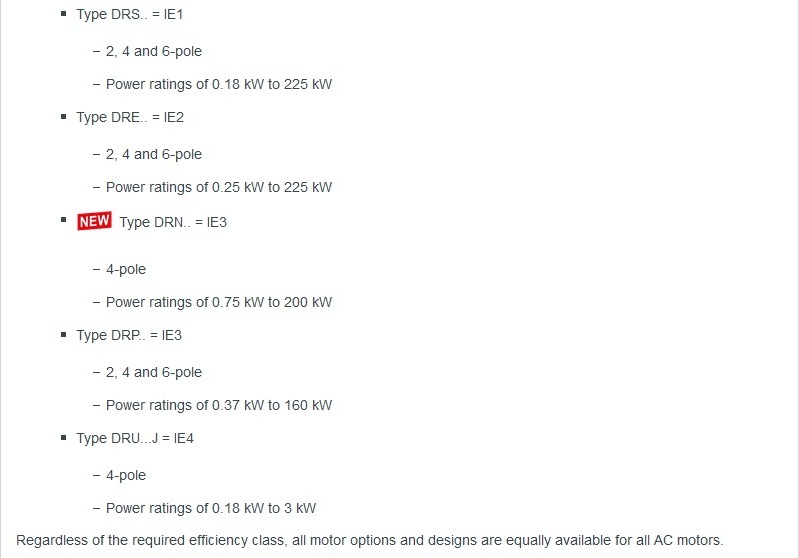

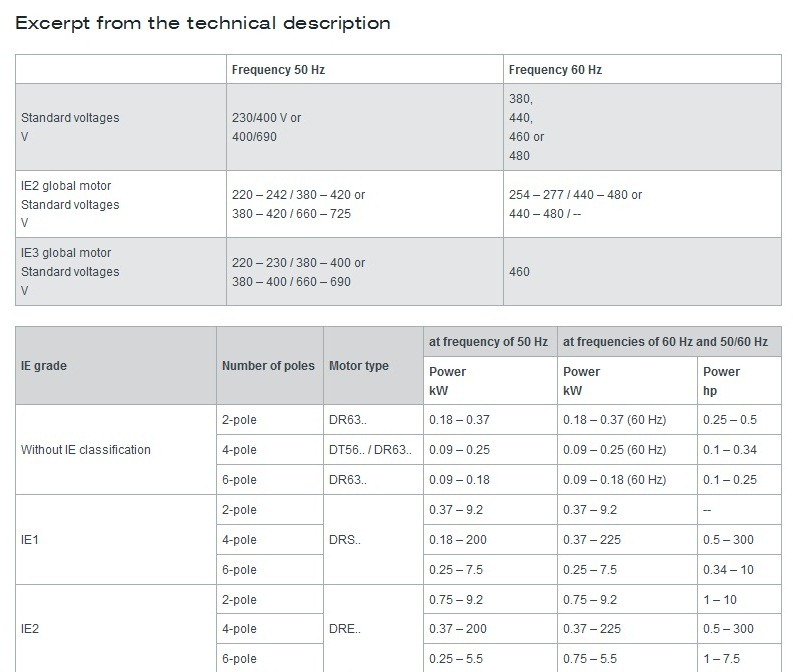

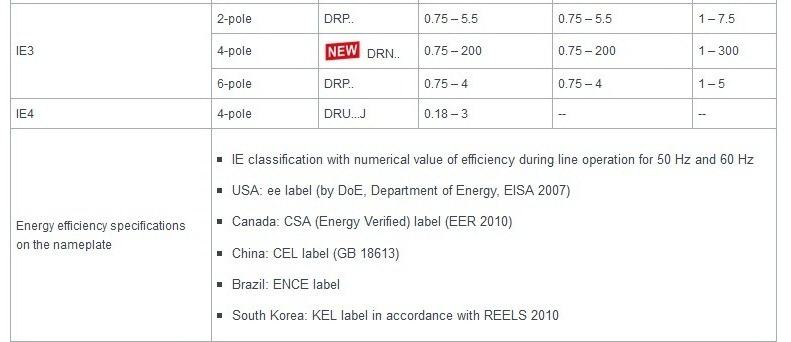

It is easy to find the ideal energy-efficient motor for your application at SEW-EURODRIVE. The DR.. series has a suitable design in its range for the globally applicable efficiency classes IE1 to IE4: DRS.. for IE1, DRE.. for IE2, DRN.. and DRP.. for IE3 and DRU.. for IE4. Select the power and frequency within this motor design and you have already taken care of the most important selection criteria.

All other motor options are of course available independently of the efficiency class. A comprehensive braking concept and cost-optimized built-in encoders ultimately complement the motor range.

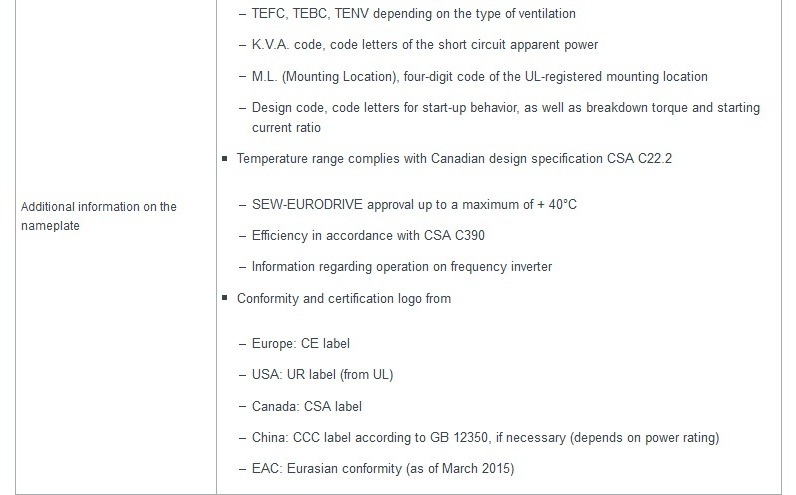

The motors of the DR.. series comply with the most important standards worldwide and the various requirements of the local energy efficiency regulations.

Motors of the DT56 and DR63 series complement the modular motor system in the range from 90 to 370 W.

Save time and optimize your motor selection, ordering and logistics processes. As a Global Player, we offer this range of products in 48 countries around the world.

Only half the solution without a gear unit? Then use our sophisticated modular system and combine an AC motor of the DR.. series with a helical, parallel shaft, worm, bevel or SPIROPLAN® gear unit of your choice. All of these gear unit types are already available off-the-shelf, combined with DR.. motors as gearmotors.

Of course, we also supply the right inverter technology for the controller and control. We develop and produce the drive electronics ourselves so that they are perfectly tailored to our motors and gearmotors, and to your application.

Your benefits

Benefit from energy efficiency

as the DR.. series offers an appropriate design for each efficiency class and can therefore be used anywhere in the world.

Extend flexibility

as the DR.. modular motor system makes millions of drive combinations possible for you - individually tailored to your requirements.

Simpler to select the right motor

because our range of motors comprises 30 performance levels, which means there is a suitable motor for practically every application.

Features

Comprehensive braking concept and combinations i.e. up to three different brake sizes per motor size featured in the range

Cost-optimized built-in encoders integrated into the motor

Significant time savings thanks to optimized processes in motor selection, order processing, and logistics

Motors for efficiency classes IE1 to IE4

Compact design saves space and costs

Future-proof, also as regards environmental protection (standards)

Reduction in operating costs when using energy-efficient motors; our energy-efficient motors conform to the efficiency classes

Standard Efficiency (IE1)

High Efficiency (IE2)

Premium Efficiency (IE3)

Super Premium Efficiency (IE4)

The “global motor” combines many energy efficiency regulations and laws in one design: the DR.. series

DR.. motors support global standards and norms

Technical Data

م

Areas of application

Applications that require a mechanical fail-safe brake

Logistics conveyor belts of all sizes

Lifting applications

Applications that require control accuracy

Positioning tasks with integrated or mounted encoders

Can be used worldwide in all industries

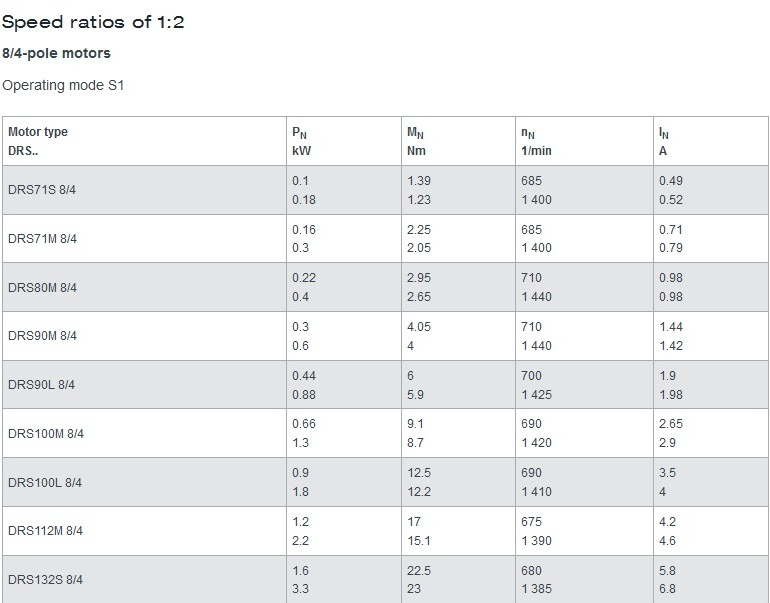

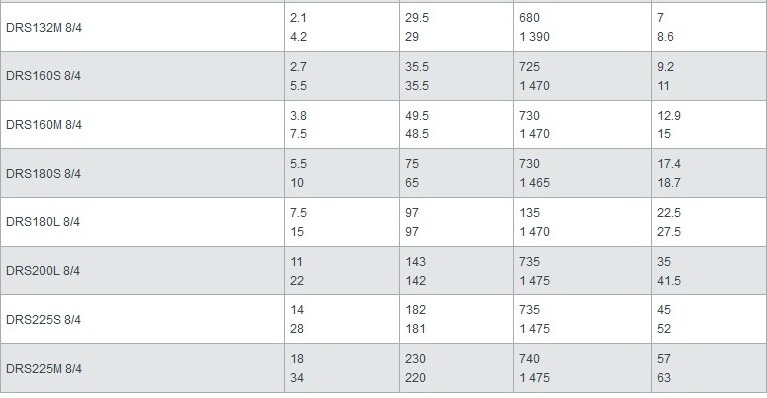

Pole-changing DR.. series AC motors (2 speeds)

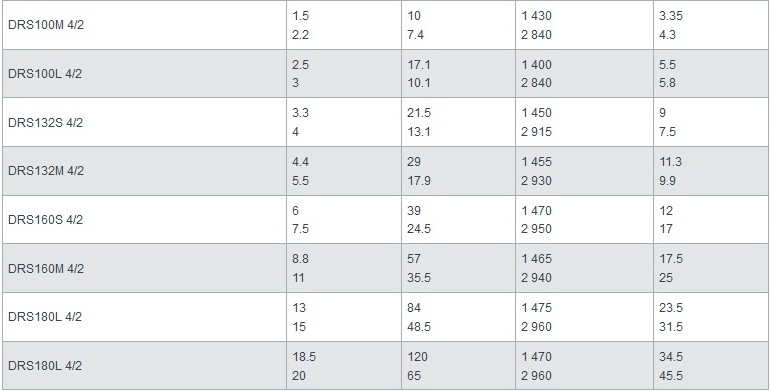

The simple way of controlling machine and plant speeds economically: 2-speed motors. We offer pole-changing DR.. series AC motors with a power combination from 0.15 kW / 0.20 kW to 18 kW / 34 kW. With this large selection, you are sure to find the suitable motor for your application.

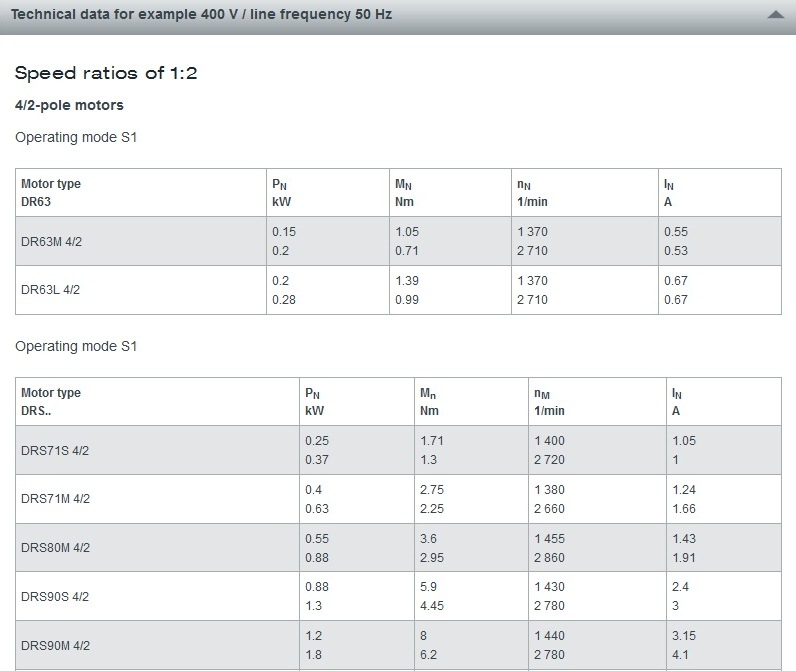

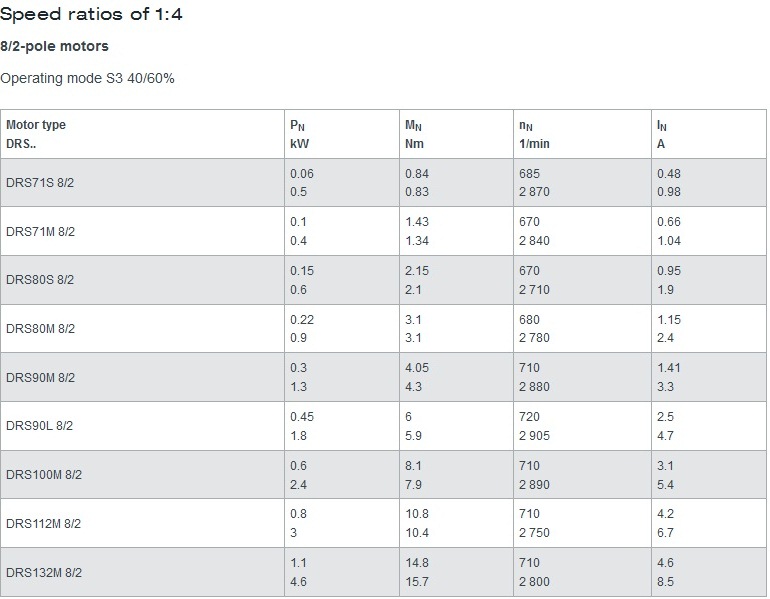

We supply pole-changing 2-speed AC motors in sizes and designs DR63 and DRS.. as 4/2 and 8/4-pole motors with speeds in a ratio of 1:2 and as 8/2-pole motors with speeds in a ratio of 1:4 (DRS.. only).

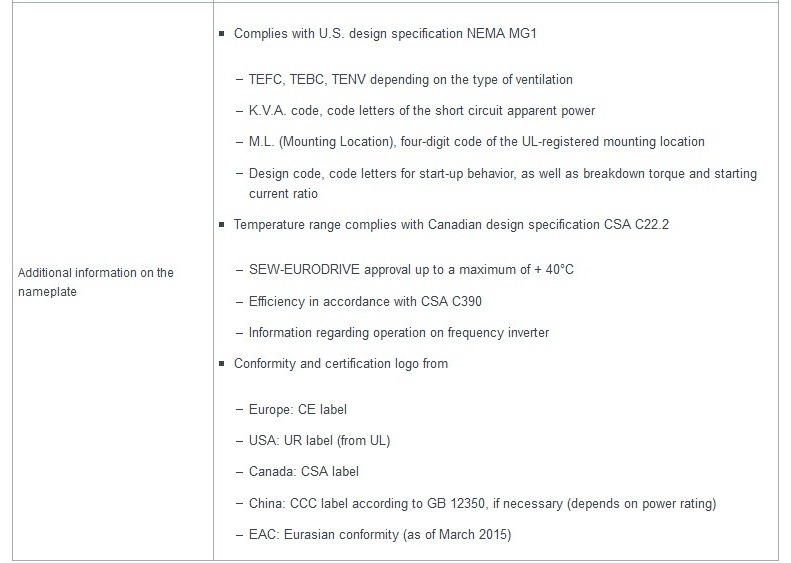

These motors also come from our modular system – take advantage of its benefits: for example, we offer pole-changing AC motors for countries with a 50 Hz or 60 Hz line frequency, with the required voltage of course. Our pole-changing motors naturally come with all the certifications required by international regulations, so you can use them anywhere in the world, for example in Canada (CAS certification), the USA (UR certification) or in China (CCC certification).

We also offer a wide range of additional features so that you can find the perfect drives to match your applications. For example, with three different brake sizes for each motor frame size, you can size the brake to ensure that braking brings the drive to a halt safely and only as fast as necessary.

Our range of pole-changing AC motors mean that you can save time and optimize your motor selection, ordering and delivery processes. As a Global Player, we offer you this range of products in 48 countries around the world.

Only half the solution without a gear unit? Then you can use our modular system to combine our DR63 and DRS.. series 2-speed pole-changing AC motors with a helical, parallel shaft, worm, bevel or SPIROPLAN® gear unit of your choice. All these gear unit types are already available serially, combined as standard gearmotors.

Your benefits

2 speeds in one motor,

allow you to reduce the motion sequences in plants and machines with two or four times the motor speed.

Proven circuit technology

can be built into the control cabinet to guarantee operation with simple and tested installation components.

Worldwide service

and standardized motor winding simplifies electrical repair of pole-changing AC motors in an emergency.

Properties

Simple winding changeover switching gives you two motor speeds

Pole-changing motors are a simple and economic option for applications that need "only" 2 speeds

Pole-changing motors are not subject to globally applicable efficiency standards, even if only one of the two speeds is continually in use

A wide variety of additional features in the SEW‑EURODRIVE modular motor system and various speed ratios (1:2 and 1:4) offer you many potential uses

We develop pole-changing motors ourselves according to our own proven modular system and manufacture them according to our own quality standards, even in our series production.

Technical data for example 400 V / line frequency 50 Hz

Areas of operation

Example 1:

To limit the mechanical load during startup, the low speed is used and then quickly switched to the high operating speed without stopping. Just before the target, the system initially switches to the lower speed to avoid missing the target position, then the drive is switched off and, in many cases, brought to a complete standstill by a brake (rapid/creep speed positioning). This type of application is used in the horizontal drives and hoists of cranes, for example.

Example 2:

Continually transporting materials in just one direction results in very different load conditions for the drive's two directions of rotation. To optimize the time the no-load return travel takes, the system switches to the higher speed and returns to the start point. This type of application is used in inclined conveyors for building materials, bulk material, etc., or cable cars and rotary tables.

Example 3:

Stepped speeds are used to handle highly variable amounts of transport goods to reduce the strain on machinery and system components. This type of application is used in conveyor belts for building materials, bulk material, packages, etc.

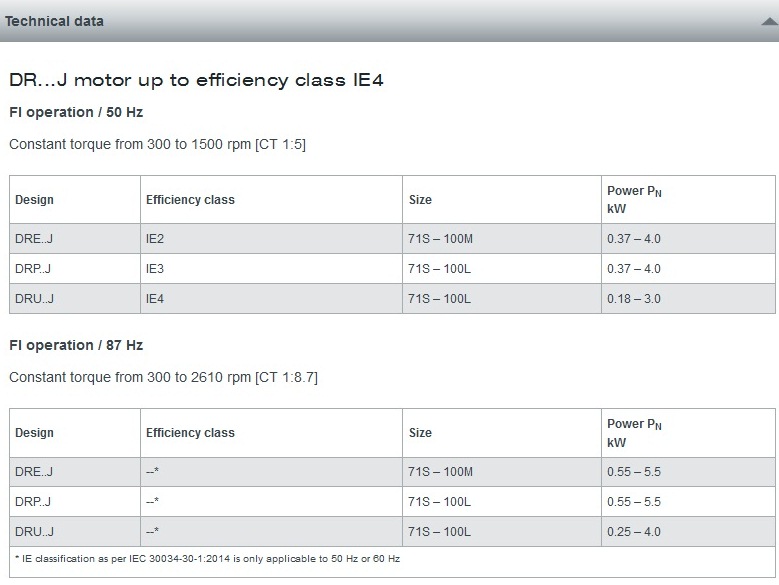

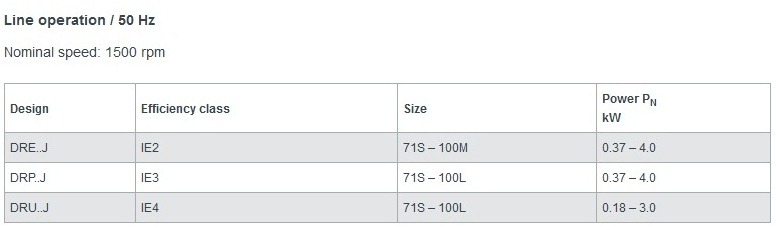

DR...J variant synchronous motors (LSPM technology)

Are you looking for a motor with the highest level of energy efficiency and a compact design? In that case, the DR...J motor with LSPM technology might be of interest to you: one motor which covers three efficiency classes. IE2, IE3 and IE4.

The Line Start Permanent Magnet (LSPM) motor is an AC asynchronous motor which contains additional permanent magnets in the rotor with a squirrel cage. After an asynchronous start, the motor synchronizes with the operating frequency and runs in synchronous mode. A motor technology which opens up new, flexible possible applications for you in drive technology.

The synchronous motors do not show any rotor losses in operation.They have an impressive degree of efficiency while maintaining a very compact design. In the same efficiency class, a DR..J motor with LSPM technology is two frame sizes smaller than a standard motor of the same power rating.

Comparison example:

A standard DRE.. motor with 1.1 kW power rating of size 90 M meets the requirements of energy efficiency class IE2. By contrast, thanks to LSMP technology, you now use “only” one DRE..J of the smaller size 80S for IE2. Efficient and profitable!

With the DR...J motors (LSPM technology), we, as a motor manufacturer, have succeeded in combining the advantages of the durable and robust asynchronous motor with those of the low-loss, compact synchronous motor. For greater efficiency in your applications.

Only half the solution without a gear unit? In that case, use our modular system and combine an LSPM motor with a helical, parallel shaft, worm, bevel gear or SPIROPLAN® gear unit of your choice. All of these gear unit types are already available off-the-shelf, combined with DR...J motors as gearmotors.

And we do of course provide the right inverter technology for the controller and control. We develop and produce the drive electronics ourselves so that they are perfectly tailored to our motors and gearmotors and to your application.

Your benefits

Extend energy efficiency

as you can use the DR...J synchronous motors anywhere in the world, also in the highest efficiency class IE4.

Reduce size

as a DR...J motor can be up to two sizes smaller than a comparable standard asynchronous motor.

Constant speed

as the DR..J motor runs at a constant speed regardless of the load, synchronous to the operating frequency without slip.

Technical data

Areas of application

Applications in continuous duty such as luggage conveyor belts in airport logistics or pump applications

Applications with high speed consistency such as spinning pump drives for material supply in textile machinery, roller drives in the glass industry or conveyor drives for coating processes

For the planning of new systems that require higher efficiencies, DR…J motors in IE4 with LSPM technology can, for example,

replace reluctance motors or

IE2 motors of the same size.

In applications in process technology, this motor with frequency inverters MOVITRAC® LTP B and MOVITRAC® B has proven to be extremely effective as a single or group drive

For applications in materials handling technology with decentralized installation, simply combine the DR...J motor with a MOVIMOT® and the associated wiring and communication options

Catalogue of DR...J variant synchronous motors (LSPM technology)

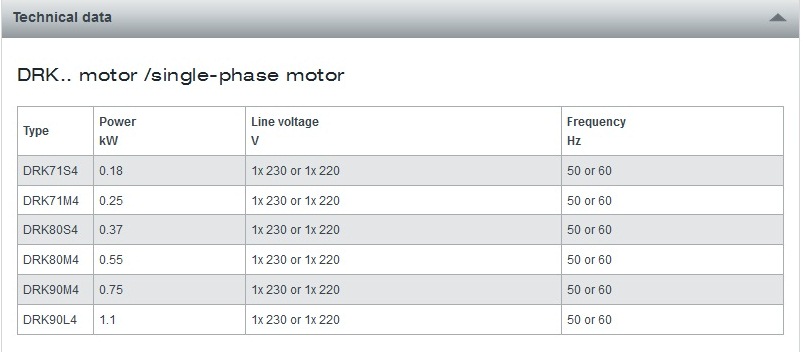

DRK..series single-phase motors

The running capacitor integrated in the terminal box is the special feature of our DRK.. single-phase motor. This does not only make the motor especially compact, it also enables application areas up to degree of protection IP66.

The compact single-phase motor with built-in running capacitor

Be it in Europe and the USA or in Brazil: you can operate the DRK.. motors in many power supplies because they are available in 50 Hz or 60 Hz with 220 V or 230 V. In total, there are six sizes available in the power range of 0.18 kW to 1.1 kW.

If you do not require a high starting torque in your applications, e.g. for fans, pumps or compactors, we recommend the DRK.. with integrated running capacitor. The motor becomes more compact as the running capacitor is housed directly in the terminal box. This means that approx. 45% to 50% of the nominal torque is available for start-up.

With an additional start-up capacitor, the motor is suitable for screw conveyors and conveyor belts as well as for agitators and dosers. You can expect a torque of approx. 100% to 150% of the nominal torque.

It goes without saying that everything fits together for single-phase motors and you can use many additional features of the DR.. modular motor system.

Only half the solution without a gear unit? No problem at all as geared single-phase motors are assembled from an extensive modular concept just like gearmotors.

Your benefits

Compact installation possible

thanks to the running capacitor integrated directly in the terminal box.

Splash-water protected

for all applications which require a high degree of protection, even outdoors.

Technical Data

Catalogue of DRK..series single-phase motors

* For more information and buy SEW equipment , kindly contact sales department.